Metal Matrix Composites (MMC)

Fibralloy™ Preforms = high performance Aluminium components.

In today’s environment, the demand for energy efficiency and high performance places ever greater demands on the design of Aluminium components. A solution already proven in the most demanding applications is MMC technology where the properties of a ceramic reinforcement material are combined with the Aluminium matrix. Using this method the designer can make large improvements in material properties while retaining the inherent low density of Aluminium.

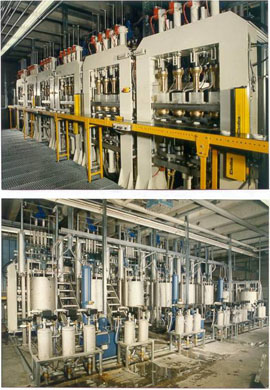

Multiple Impression Dewatering Presses

Examples of the material properties that can be improved using a suitable Aluminium/Ceramic composite:

- Tensile strength (especially above 300°C)

- Fatigue life

- Wear resistance

- Stiffness

- Creep resistance.

Fibralloy™ experience at Sitek

For over 25 years, the Fibralloy™ manufacturing unit at Wissembourg has supplied ceramic preforms for use in Aluminium casting to the automotive, aerospace and armour industries in Europe and USA. The final uses of this technology are varied but most common is the reinforcement of the piston crown in passenger car, commercial vehicle and off-road Diesel engine applications. This use is a good example of the benefits that Sitek can bring to the design of reinforced components. Sitek works closely with the component designer and will develop a preform which provides selective reinforcement in the highly stressed part of the final cast component. This approach optimises performance and reduces the cost compared with reinforcing the full cast volume.

Unique materials processing know-how

Many years of developing preforms, combined with close links to the suppliers of high temperature fibres and ceramic powders, has resulted in a unique skill set well adapted to controlling the desired preform characteristics. High Alumina fibres can be controlled to have zero shot content and adjusted for compaction to give a specified fibre volume. Sitek have the know-how, through materials processing and the combination of ceramic materials to provide preforms with a ceramic volume fraction as low as 7% and as high as 40%. This creates huge scope for adjusting the properties of the final cast component.

Diesel Engine Piston |

Preform Reinforcement Rings |

Sitek Fibralloy™ services

Development

Sitek work with the component designer to optimise the design of the reinforcement at the same time that the component is being developed. Initial prototypes can be supplied by machining from a block prior to fixing the design for future volume production. Tolerances of +/- 0.5mm are possible in the preform dimensions.

Prototypes

Sitek is well equipped to supply initial prototypes gradually increasing output to serial production, produced on dedicated net-shape tooling. Pre-forms up to 800x300x125 mm are within the normal prototyping size range.

Serial Production

Sitek is equipped with multiple impression semi-automatic dewatering presses to make large volume serial production runs. Series production of parts at rates up to 10,000 parts per month is possible.

Contact Sitek Fibralloy™ services

Contact the preforms business at Wissembourg direct on:

+33 3 88 54 87 33

English, French and German languages are spoken.

Or send an E-mail to:

preforms.info@sitekinsulation.com.

Fibralloy™ Business Development:

Fibralloy™ preforms can also be contacted via our business development partner: